MCR-30

- • 30 KILOGRAM (66 POUND) BATCH CAPACITY

- • AUTOMATION READY

- • DIGITAL ROASTING SYSTEM

- • OPERATOR-ASSIST SENSOR PACKAGE

- • CSA® DESIGN CERTIFIED

- • CREATES $5069+/HOUR

Dogwood Coffee in Minneapolis, MN

Mill City Roasters®

30 Kilogram Coffee Roaster with Loader, MCR-30

Call for pricing: (612) 886-2089

At the top of our line of roasters the MCR-30 and MC-60 model coffee roasters have set a new industry standard for roast quality at scale.

The MCR-30 is a massively overbuilt specialty coffee production platform capable of maintaining the most delicate flavor profiles at a production volume previously undreamed of.

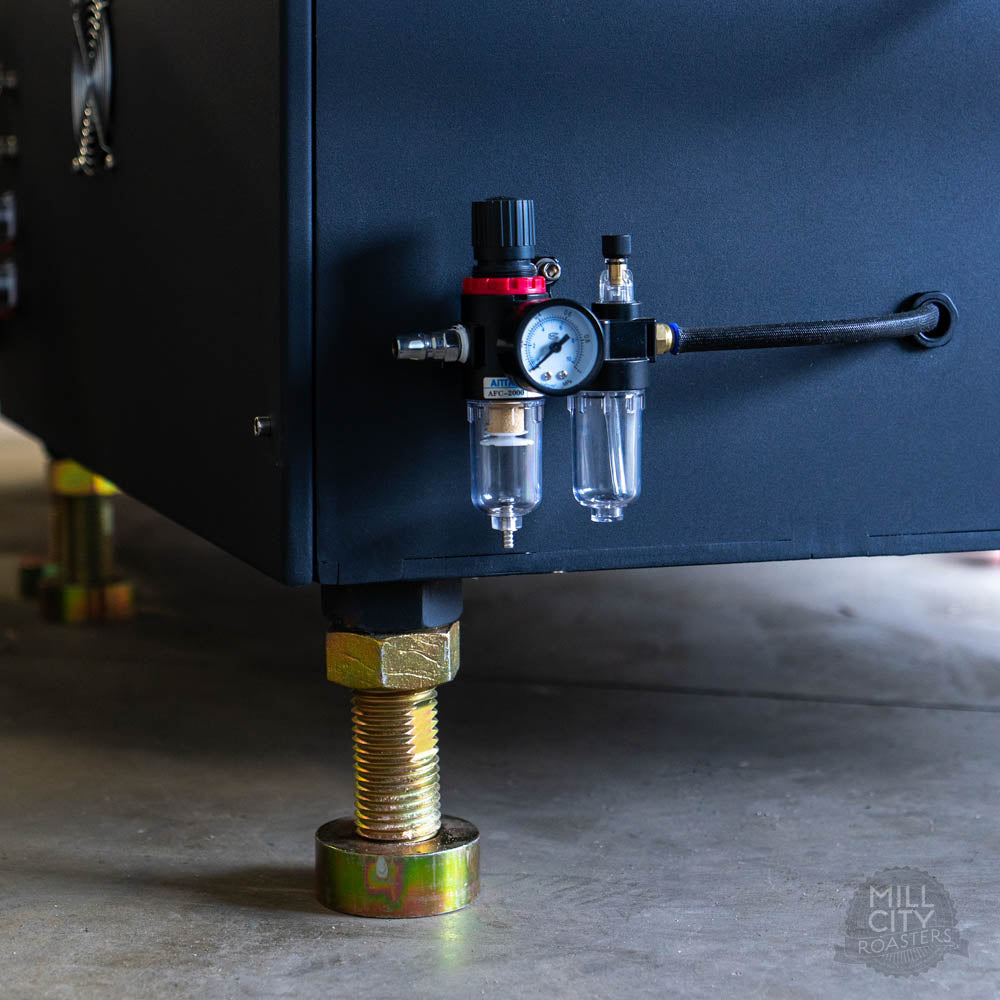

The MCR-30 is built on a gigantic double walled and fully insulated monolithic weldment chassis specifically calculated for maximum stability, fuel efficiency and pinpoint roast control. Similar to our other models the roaster is equipped with dedicated high pressure centrifugal blower roaster exhaust and cooling tray fans that allow for simultaneous roasting and cooling. It is fully RoastPATH Automation capable. Because of the large size of the machine and the height of the charging hopper, we include a high performance “rapid fill” pneumatic coffee loader with programmable integrated scale with every roaster.. This system allows a single operator to easily exceed over 1700 lbs of the highest quality finished coffee per day.

The all-digital control system integrates seamlessly with RoastPATH®, including the highly requested Roast Replay feature. During the roast, RoatsPATH® automatically logs BT, ET, IT and DT temperature readings, as well as fuel setting changes, and fan, fuel and drum speed adjustments. Direct drum pressure is also logged as a feedback loop for operator controlled roast airflow changes.

Total control over your fuel, fan and drum speed allows you remarkable flexibility in your batch size. You can easily scale your batch size up or down without sacrificing quality to focus on a special green or small project.

This model includes the Operator Assist System which automatically recovers to production charge temperature settings, starts timers, and triggers the cooling tray fan and stirring arms off/on at discharge from the drum or cooling tray. It can be configured to automatically charge the drum and discharge into the cooling tray upon the conclusion of the roast. This system also incorporates position sensors that make it nearly impossible to accidentally discharge green coffee from the drum into a cooling tray filled with roasted coffee.

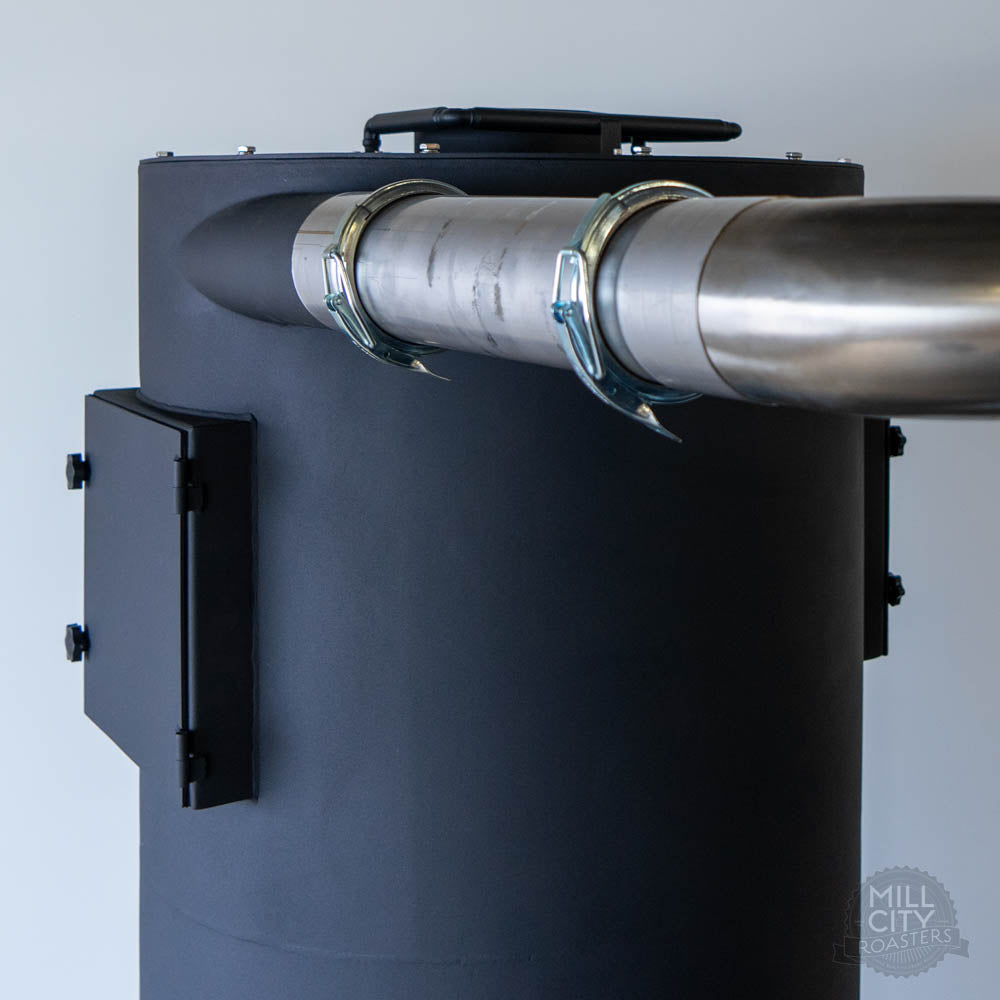

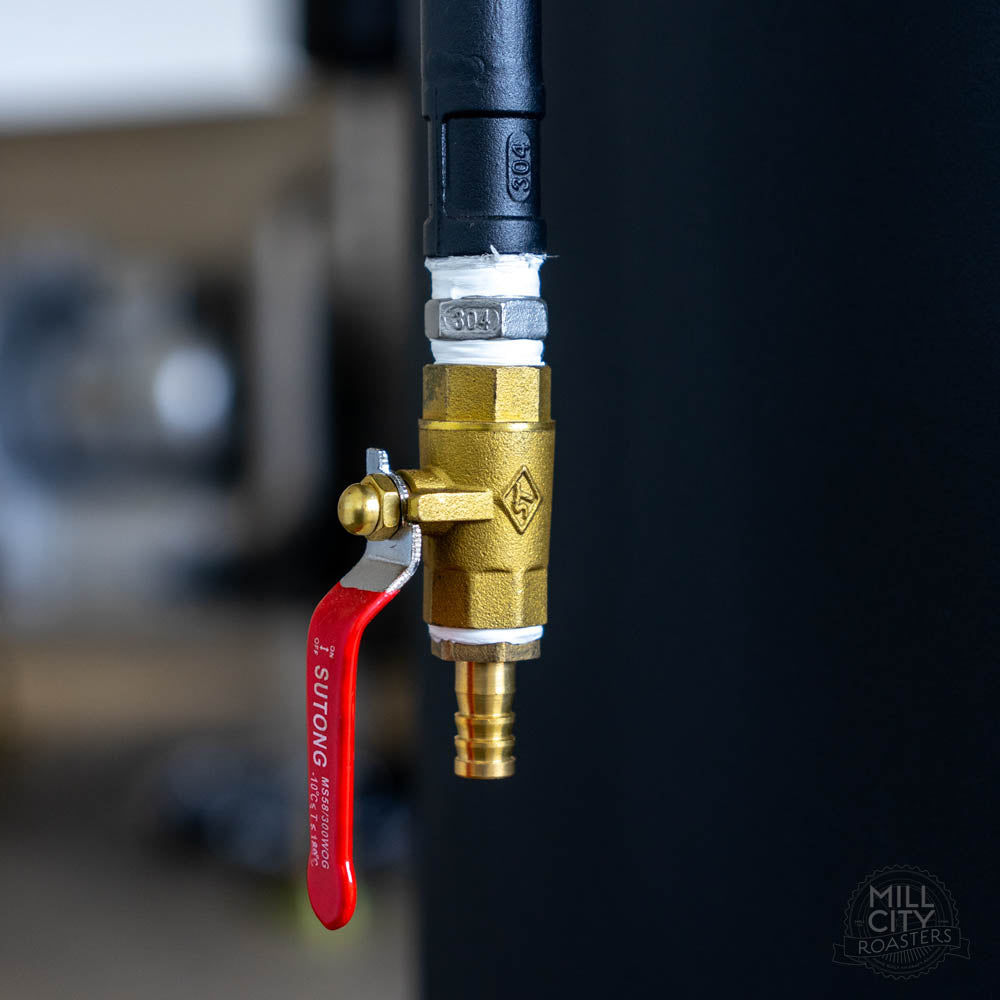

The high capacity chaff collector fully disassembles for easy cleaning and include an emergency water quench protection valve to recover quickly and safely in the event of an unexpected chaff fire.

High capacity cooling trays and stirring arms are designed to hold 3 full batches for post-roast blending. The enormous high performance cooling fan cools 2nd crack roasts within 4 minutes.

- Choose from three optional layouts using our Quick-Connect kits to arrange components and exhuast -or- request a custom layout

- Optional UL® NSF (National Food Safety) package.

Call for pricing: (612) 886-2089

Next available: 1 in-stock in Minneapolis!

Photo by Dogwood Coffee in Minneapolis, MN

PRODUCTIVE CAPACITY

THE MCR-30 CREATES $5069 PER HOUR

Roasting 4 full batches an hour on an MCR-30 creates over 211 pounds of roasted coffee every hour. This yield is enough roasted coffee to fill more than 211 12-ounce bags. With a retail value of $18 per 12-ounce bag, you can create $5069 of retail coffee per hour.

Want to see how your business expenses stack up against that income? Use our Roaster Income Calculator to use your real-life expenses and find a roaster capacity that works for your business plan.

Features

Planning & Installation

Take a closer look